How Do TT Transmitters Optimize Temperature Monitoring Systems?

What Are TT Transmitters and How Do They Work?

What Is a TT Transmitter?

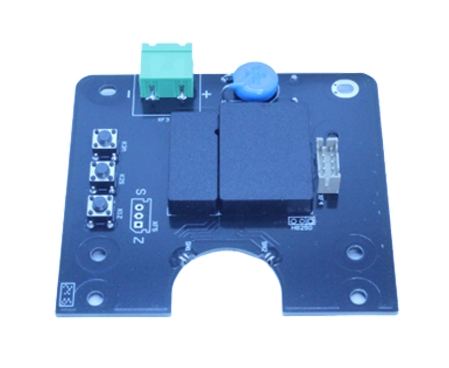

The function of a temperature transmitter (TT transmitter) is to gauge and relay temperature information from a sensor to a control unit system in a manner for easier analysis and utilization by users.

How Does a TT Transmitter Function in a Temperature Monitoring System?

In temperature monitoring systems, the TT transmitter plays a vital role. It collects signals from connected sensors. These signals usually come as millivolt readings or resistance values. Control systems can’t use these signals directly. The transmitter converts them into usable formats. The outputs may be 4-20 mA current loops. Alternatively, they could be digital protocols like HART or Modbus. This conversion guarantees data transmission over extended distances, without notable signal loss.

Why Are TT Transmitters Essential for Accurate Temperature Measurement?

TT transmitters improve temperature measurement accuracy. They boost data reliability by amplifying and converting signals. This reduces errors caused by noise or interference. Many TT transmitters also have extra features. These include linearization and sensor-specific compensation. Such functions help maintain accuracy across different industrial applications.

Key Features of TT Transmitters in Temperature Monitoring Systems

What Makes TT Transmitters Reliable for Industrial Applications?

High Accuracy and Stability in Measurements

TT transmitters are known for their precision and reliability in providing measurements thanks to their sophisticated calibration methods and internal adjustments that factor in changes like temperature shifts and electrical interferences over time.

Compatibility with Various Sensors (e.g., RTDs, Thermocouples)

TT transmitters are made to work with various temperature sensors like RTDs and thermocouples. This flexibility enables their use in industries and scenarios ranging from manufacturing operations to HVAC systems.

How Do TT Transmitters Enhance Signal Transmission?

Signal Conversion and Amplification

TT transmitters enhance signal transmission by transforming analog signals from sensors into standardized outputs that can travel extended distances without losing quality or strength. Amplification guarantees that control systems can precisely interpret the weakest sensor signals.

Reducing Noise and Interference

In settings where electromagnetic interference may disrupt data accuracy, TT transmitters play a crucial role in preserving signal quality by isolating sensor signals from external noise sources and utilizing filtering methods.

The Role of ICwalk Products in Temperature Monitoring Optimization

How Does ICwalk’s Technology Improve TT Transmitter Performance?

Advanced Sensor Integration Capabilities

ICwalk’s items are designed with cutting-edge sensor integration features that enable connections with different temperature sensors, guaranteeing accurate calibration and adaptability across a range of platforms.

Enhanced Data Communication Protocols

ICwalk integrates data communication protocols into their TT transmitters to ensure seamless data flow between devices and support real-time monitoring and diagnostics capabilities for users to efficiently optimize their temperature monitoring systems.

Why Choose ICwalk TT Transmitters for Your Monitoring System?

ICwalk’s TT transmitters are known for their design and features that are specifically crafted for industrial use cases. They provide solutions for precise temperature measurement and monitoring requirements.

Applications of TT Transmitters Across Different Industries

Where Are TT Transmitters Commonly Used?

Manufacturing and Process Industries

Temperature transmitters are widely used in manufacturing and process industries. They ensure accurate temperature measurements. These measurements are essential for operational reliability and consistency. Many industries depend on precise temperature control. Proper regulation is crucial for product quality and safety. For example, chemical production requires strict temperature control during reactions. This maintains product integrity and prevents risks. Likewise, food processing needs precise temperature tracking. It ensures compliance with regulations and product quality.

By incorporating TT transmitters into these systems and enabling real time monitoring and control capabilities through them manufacturers can promptly address any deviations that occur ensuring downtime and improved productivity overall ICwalk’s TT transmitters are tailored with sophisticated functionalities to meet the requirements of challenging settings Their durable build and ability to work with different sensors make them a popular option for industrial uses.

HVAC Systems and Energy Management

In heating and cooling systems like HVAC (Heating Ventilation and Air Conditioning), TT transmitters are vital for maintaining energy efficiency and controlling climate conditions effectively. These tools keep track of temperature changes in areas to make precise modifications that improve comfort levels and lower energy usage. For instance, in office buildings or factories, TT transmitters are essential for keeping temperatures stable by supplying accurate information to automated control systems.

Energy control systems also see advantages from incorporating TT transmitters into their operations as they provide accurate temperature information that aids in making informed choices about energy consumption levels. ICwalk’s technology stands out in this field for its precision and consistent performance across environmental settings.

How Do TT Transmitters Contribute to Operational Efficiency?

TT transmitters play a role in enhancing operational effectiveness by guaranteeing precise temperature monitoring—an essential element in streamlining operations in different sectors. They excel at transforming sensor signals into standardized outputs to enable smooth interaction with control systems. This not only enhances data precision but also minimizes the risk of errors triggered by signal weakening or disturbances.

Furthermore, a lot of TT transmitters come with sophisticated diagnostic capabilities that offer real time information about how the system is working. Operators can use these functions to spot issues and prevent them from becoming bigger problems; this helps cut down maintenance expenses and avoid unexpected shutdowns. ICwalk’s products are known for their performance in important situations thanks to these innovative features.

Advantages of Using ICwalk’s TT Transmitter Solutions

What Benefits Do ICwalk’s Products Offer Over Traditional Systems?

Improved Accuracy and Reliability in Harsh Environments

ICwalk’s TT transmitters deliver accurate and reliable performance even in tough industrial settings. These environments often expose equipment to extreme heat or cold. They may also contain corrosive chemicals. Such conditions could negatively impact device performance. However, ICwalk’s uses durable materials in their products. They incorporate advanced technologies too. This combination ensures consistent operation in harsh conditions.

Their transmitters come with integrated compensation mechanisms that adjust for changes in the environment such as interference or fluctuations in temperature to maintain consistent measurements over time. Perfect for situations demanding utmost accuracy.

Cost-Effective Maintenance and Scalability Options

ICwalk’s designs their TT transmitters with cost-effectiveness in mind. Their solutions feature a simple structure. This makes upgrades or replacements easy. Companies don’t need complicated system overhauls. Businesses can adapt their monitoring systems as needs evolve.

These devices require little maintenance. This reduces long-term costs. Built-in troubleshooting features help too. Technicians can fix issues remotely. They don’t always need to visit the equipment in person.

Businesses seeking to improve their temperature monitoring systems without breaking the bank can find a balance of quality and cost effectiveness in the solutions offered by ICwalk.

FAQ

Q: Which sensors can be used with TT transmitters?

A: TT transmitters can work with sensors like RTDs (Resistance Temperature Detectors) and thermocouples, making them suitable for a wide array of applications.

Q: How do TT transmitters enhance the transmission of signals?

A: They transform low-strength analog signals from sensors into outputs such as 4 to 20 mA current loops or digital protocols like HART or Modbus, guaranteeing precise data transmission across extended distances with minimal signal deterioration.

Q: What makes ICwalk’s products stand out from the rest of the competition?

A: ICwalk provides cutting-edge features like improved sensor integration capabilities and advanced communication protocols tailored for performance in industrial settings, at a cost-effective and scalable level.

Q: Are the TT transmitters from ICwalk appropriate for use in energy management systems?

A: Certainly! ICwalk’s solutions work well for managing energy because they are super accurate and reliable, even when dealing with different environmental conditions.