What Makes the Flow Transmitter Board Crucial for Precise Data Transmission?

Understanding the Role of a Flow Transmitter Board

What Is a Flow Transmitter Board and How Does It Work?

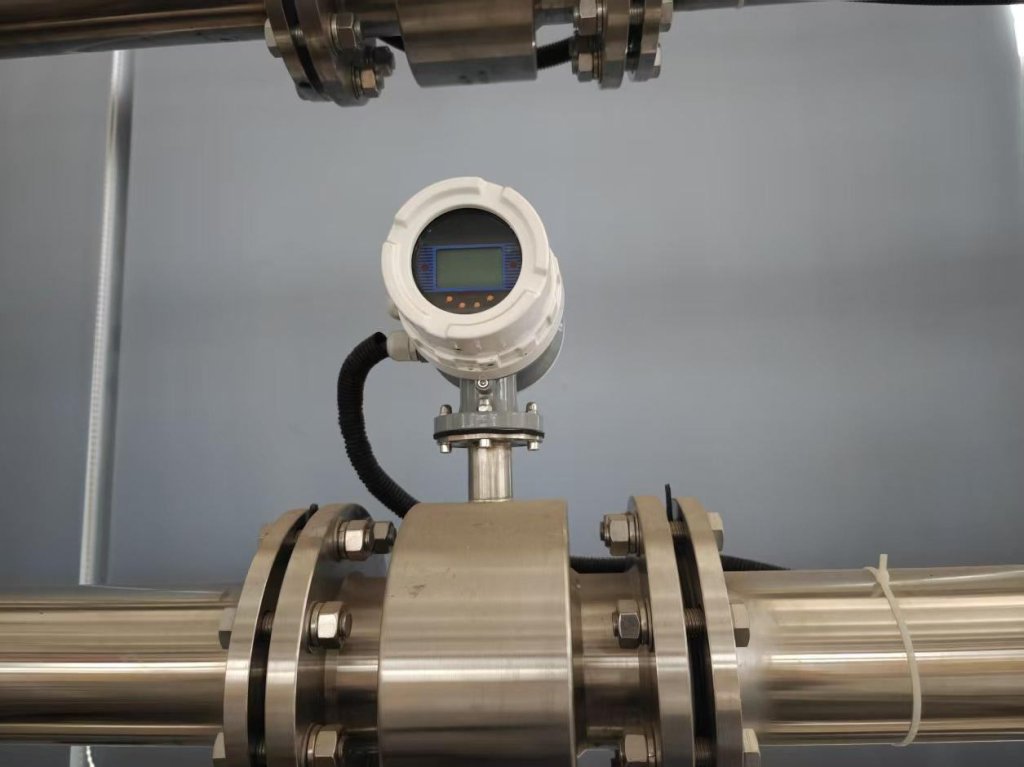

A flow transmitter board is a key electronic component. It processes raw signals from flow sensors and converts them into standard output signals. These signals are used for measurement, monitoring or control. The board is critical for capturing fluid dynamics accurately. It is designed to handle data from various flow sensors. These include vortex, electromagnetic, ultrasonic and rotameter-based sensors. The board transmits data in formats like 4-20 mA, RS485 or HART protocols.

Why Is Accurate Data Transmission Vital in Flow Measurement?

Precise data transmission is essential. It ensures fluid flow rates are measured with minimal errors. This is crucial for efficient operations. It also ensures safety and regulatory compliance. Inaccurate data can cause issues. For example, it may lead to resource waste in chemical dosing. It can also cause system failures in water distribution. In worst cases, it may create hazardous conditions.

How Does the Flow Transmitter Board Connect with Other System Components?

The flow transmitter board serves as a bridge. It links the sensor to control systems like PLCs or SCADA. It receives analog signals from the sensor. It processes them using signal conditioning. Then, it converts them into formats suitable for downstream equipment. Many boards offer real-time diagnostics. They also support protocol communication. This ensures smooth integration in complex systems.

Core Features That Ensure Precision in Flow Transmitter Boards

What Factors Affect the Accuracy of a Flow Transmitter Board?

Several elements impact accuracy. These include signal processing, environmental compensation and calibration precision. Sensor compatibility and noise immunity also play roles. High-quality boards use advanced algorithms. These filter out interference. They provide stable outputs under varying conditions.

The H8250FZ intelligent float transmeter board is built for high-performance metal rotameter flow transmitters with HART protocol. It offers high-precision measurement. It ensures stability and reliability. It is vital in many industrial applications.

How Do Signal Conversion and Noise Reduction Improve Precision?

Analog-to-Digital Signal Processing

Signal conversion turns analog sensor signals into digital values. Control systems can process these values. High-resolution ADCs detect small flow changes accurately. This is critical for micro-flow applications. Sensitivity is key in these scenarios.

Temperature Compensation Mechanisms

Temperature changes affect fluid properties, including viscosity and density. Advanced boards include temperature sensors. They may also use compensation algorithms. These adjust readings dynamically. The H880TH Universal Vortex Flow Transmitter supports temperature and pressure compensation. It ensures accurate measurements in varying conditions.

Signal Filtering and Calibration Capabilities

Filtering removes electrical noise. Noise can distort sensor signals. Calibration allows users to correct baseline errors. It also lets them adjust span settings for specific uses. The board uses advanced signal processing. This eliminates interference effectively. It keeps measurement results within ±0.35% under standard conditions.

ICwalk’s Approach to High-Precision Flow Transmitter Boards

Who Is ICwalk and What Solutions Do They Provide?

ICwalk specializes in high-performance electronic modules. We design and manufacture flow transmitter boards. These are tailored for various industrial applications. Our products include the Vortex Flow Transmitter Board, Ultrasonic Open Channel Flow Transmitter Board, Micro-flow Metal-tube Flow Transmitter Board, Intelligent Metal Tube Rotor Flow Transmitter Board and Electromagnetic Flow Transmitter Board E4000. Each is designed for specific sensing technologies.

What Makes ICwalk’s Flow Transmitter Boards Unique?

Key Design Principles in ICwalk’s Product Line

Our products focus on modularity and precision engineering. They use robust signal processing algorithms. They are compatible with standards like HART and RS485. They offer excellent long-term stability. They maintain performance in complex environments. This reduces errors from environmental changes.

Integration with Diverse Sensor Types

ICwalk’s boards work with various sensors. These include metal tube rotameters (e.g., H8250FZ), vortex sensors (e.g., H880WJ), electromagnetic sensors (e.g., E4000 Series) and ultrasonic level devices (e.g., H760RO). This versatility allows clients to use our solutions across multiple fields. They don’t need separate platforms.

Emphasis on Stability and Long-Term Reliability

Our designs prioritize durability. They feature wide range ratios up to 1500:1. They offer fast response speeds for real-time monitoring. They include robust enclosures for harsh environments. They quickly reflect fluid flow changes. This ensures accurate real-time data.

Applications Across Industries Requiring Accurate Flow Data

In Which Sectors Are Flow Transmitter Boards Most Essential?

Flow transmitter boards are critical in many sectors. These include water treatment, pharmaceuticals, energy production, food processing, chemical manufacturing, agriculture irrigation and environmental protection.

The H8250FZ is widely used in municipal water supply and drainage. It is also used in chemical and petroleum industries. It serves the food and beverage sector. It supports environmental protection and agricultural irrigation.

How Do Industries Benefit from Precise Data Transmission?

Accurate data optimizes processes. It maintains ideal operating conditions. For example, it controls reactant dosages in chemical plants. It ensures consistent quality in beverage filling.

Life Sciences and Laboratory Automation

Micro-flow metal-tube transmitters like the H837FZ are ideal here. They are sensitive to low volumes. They regulate reagent flows precisely in automated testing.

Chemical Processing and Energy Transition

Volatile fluids are common in these sectors. Electromagnetic transmitters like the E4000 series provide non-intrusive measurements. These are vital for process safety.

Food & Beverage Quality Control

Reliable measurements prevent overflows or shortages during bottling. Non-contact methods like the H760RO ultrasonic open channel flow transmitter board ensure hygiene standards.

The Importance of Choosing the Right Flow Transmitter Board

How Does an Optimized Transmitter Board Improve System Performance?

An optimized board ensures consistent performance. It minimizes drift errors over time. It offers fast response times. These are critical for dynamic process control. It reduces downtime from recalibration or signal loss. This boosts productivity across operations.

Why Should Users Choose Professional-Grade Solutions Like ICwalk’s?

Professional-grade solutions offer long-term reliability. They are backed by engineering expertise. ICwalk provides more than hardware. We offer full technical support. This covers selection through maintenance.

FAQ

Q: What Should I Consider When Choosing a Flow Transmitter Board?

Key factors include sensor compatibility (vortex, rotameter, electromagnetic). Consider required protocols (HART, RS485). Check accuracy specifications (±%). Evaluate environmental conditions like temperature and pressure. Response time, output format (analog/digital) and power supply (battery/DC) are also important.

Q: Can ICwalk’s Products Be Customized for Specific Needs?

Yes. We offer tailored solutions. These include micro-flow detection modules and battery-powered units for remote installations. Contact us at linda@icwalk.com. You can also visit Room 701, No.1 Shangdi East Road for consultation.

Q: Are ICwalk’s Boards Compatible with Digital Communication Protocols?

Yes. Our products support RS485 + Modbus RTU and HART standards. This depends on the model. They integrate easily into modern control systems.